PRE-ORDER TICKET FOR H2C AMS COMBO

Standard

- Hotend Change Multi-material Printing

- Minimal Purge Waste Multi-Color Printing

- Precise & Fast Inductive Nozzle Heating

- Close-loop Servo Extruder

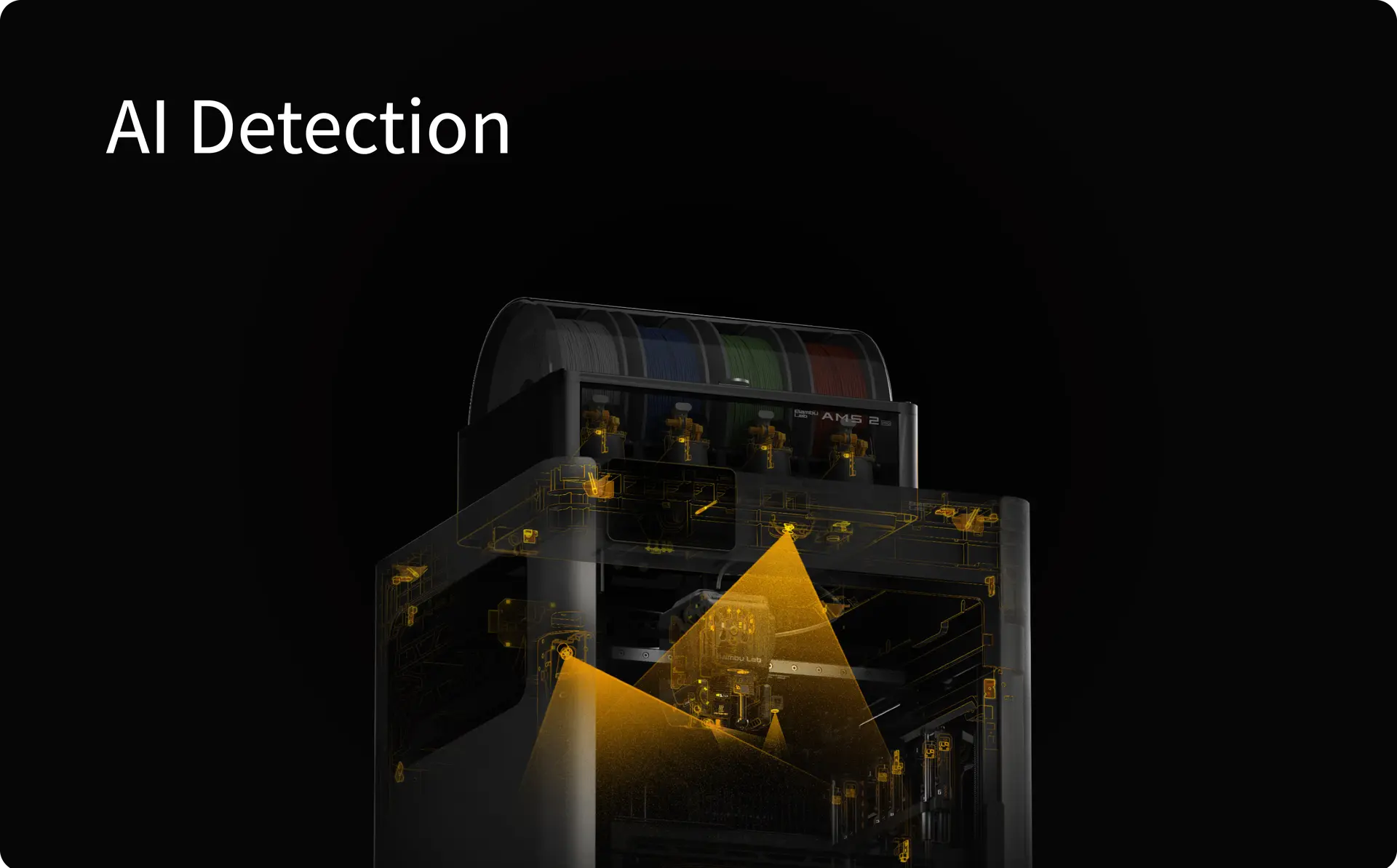

- Full Filament Path AI Error Detection

- 330*320*325 mm³ Build Volume

- Vortek 6-hotend automatic swap system

- H2C

- AMS 2 Pro

- 1 Normal 0.4mm Hardened Steel Hotend

- 4 Vortek 0.4mm Induction Hotend

- 1 Vortek 0.2mm Induction Hotend

- 1 Vortek 0.6mm Induction Hotend

- 5μm Resolution Optical Motion Calibration

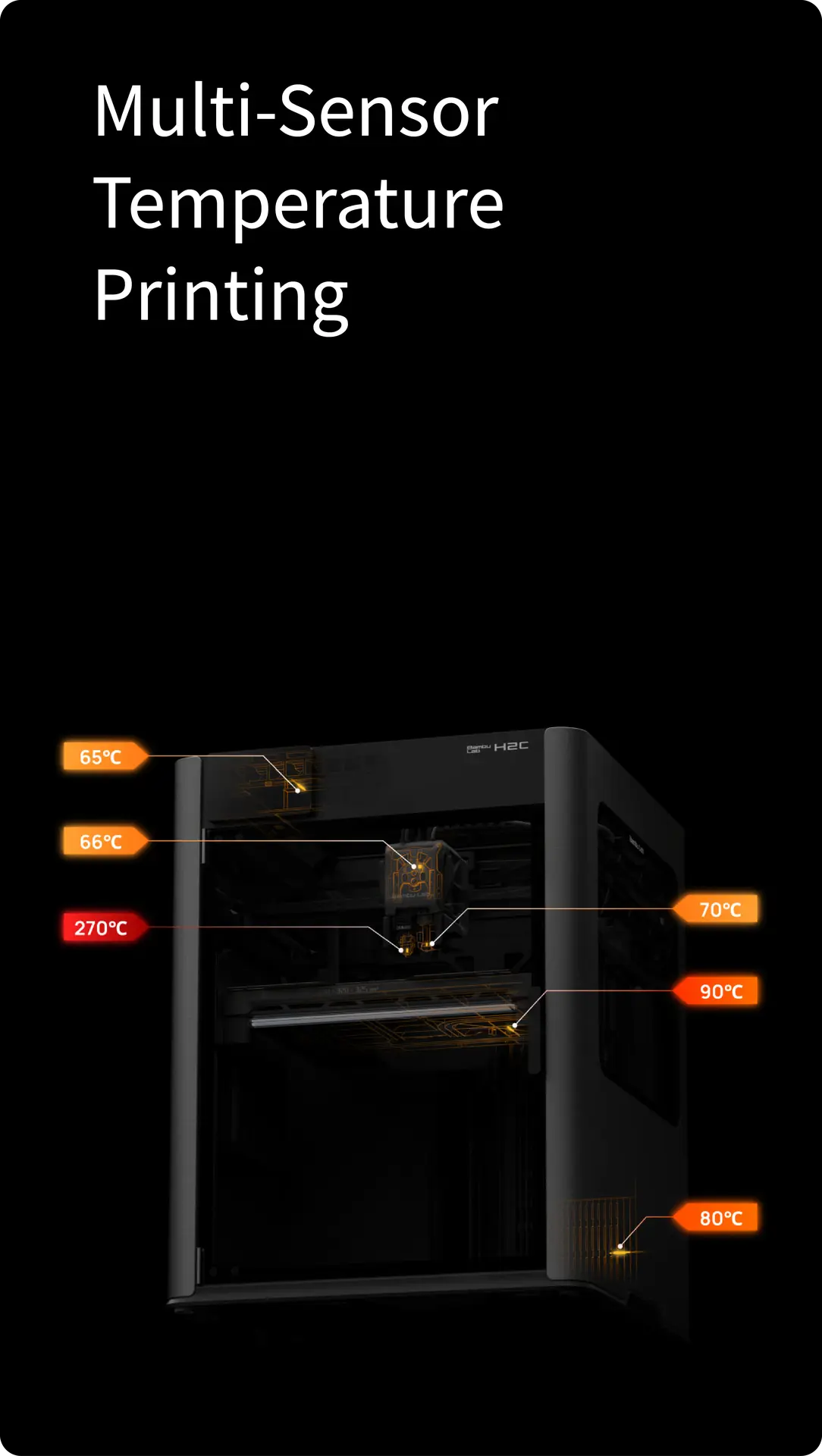

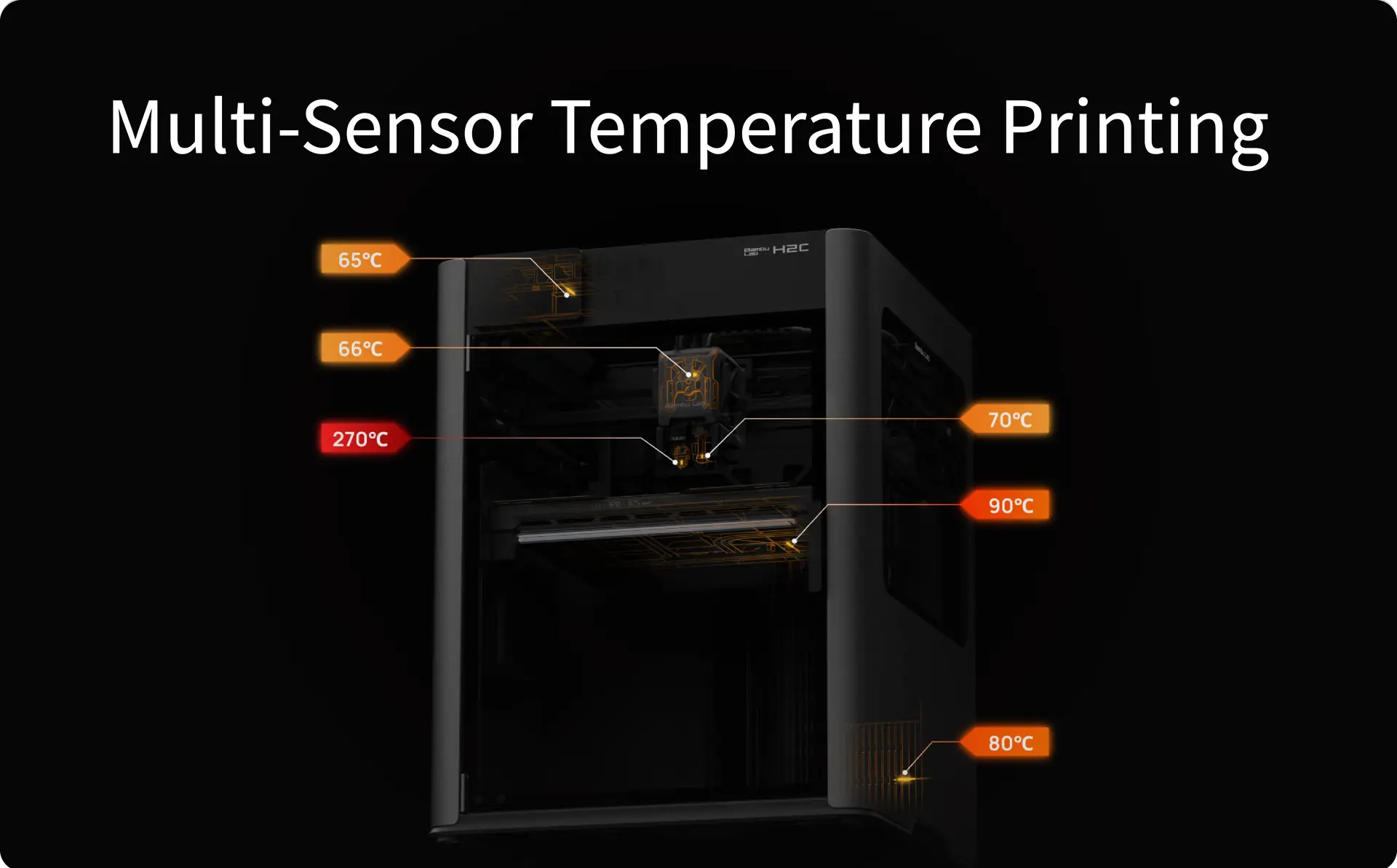

- 350°C Nozzle & 65°C Active Chamber Heating

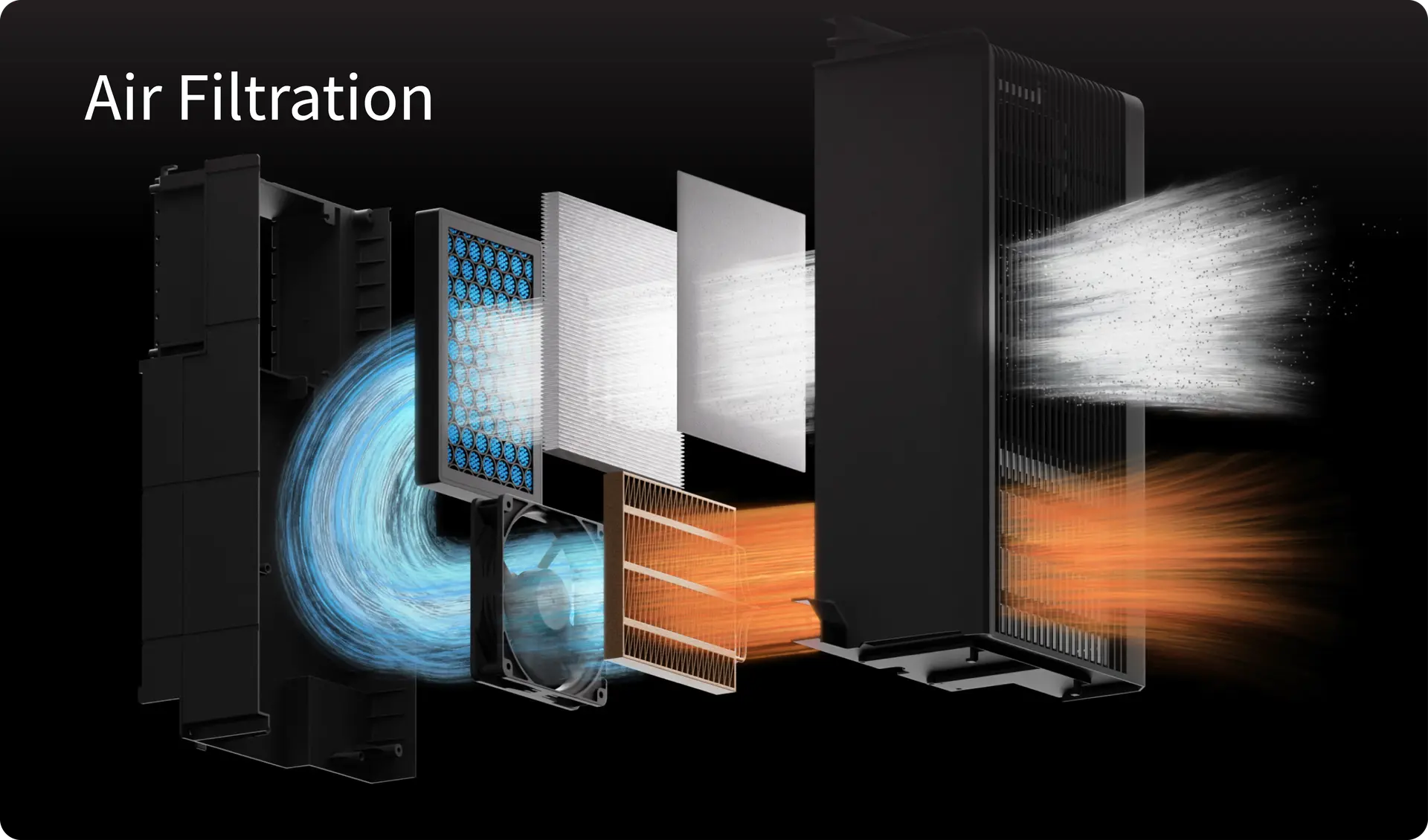

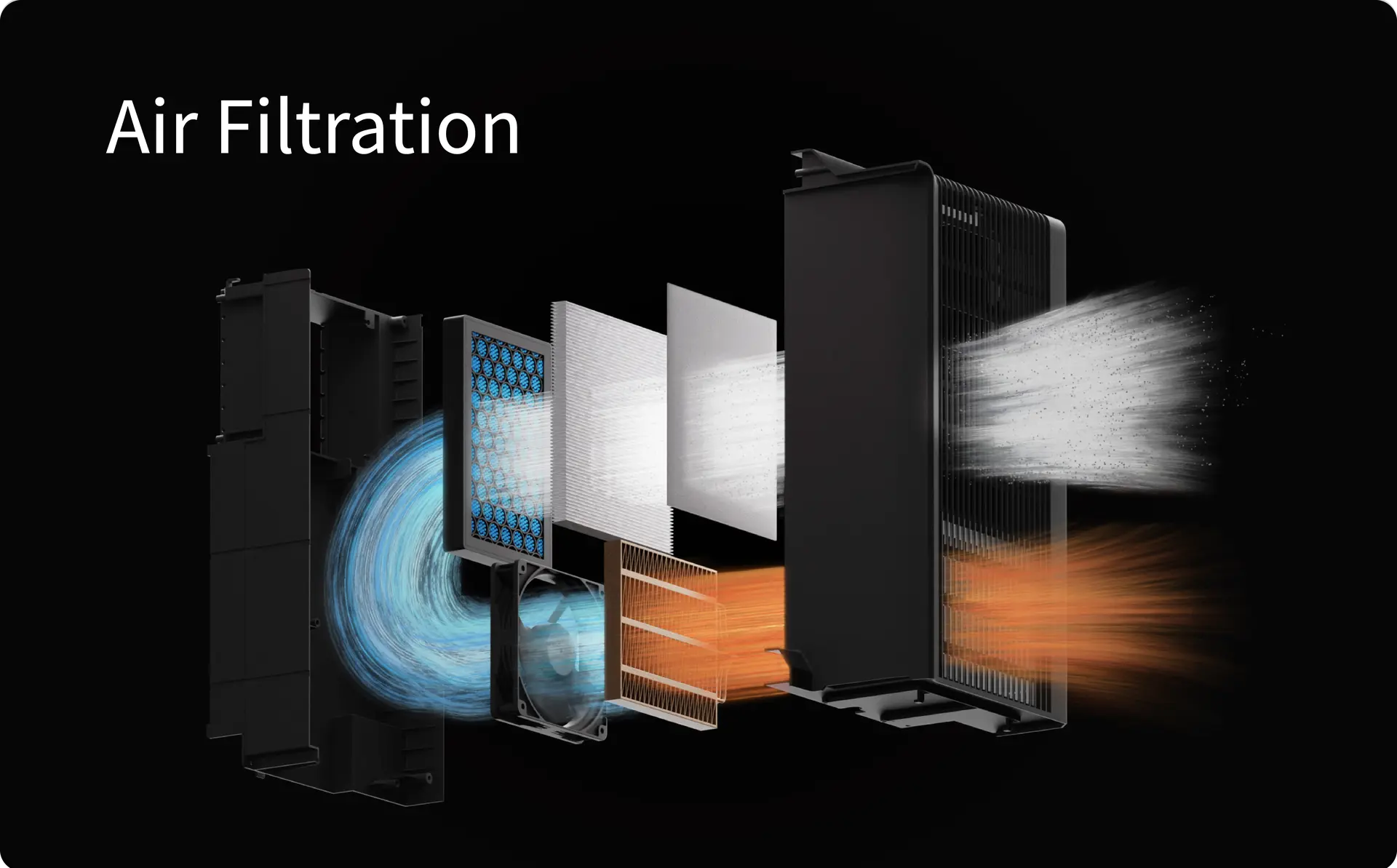

- Best-In-Class Air Filtration

Description

To get the most out of the H2C, you’ll need at least two 4-slot AMS units and six matching induction hotends. The Ultimate Set includes these and adds extra hotends for expanded use.

| Marque: Bambu Lab |

Bambu Lab H2C

Uncompromising Multi-Material

Paint No More, Print 7 Colors in One-Piece

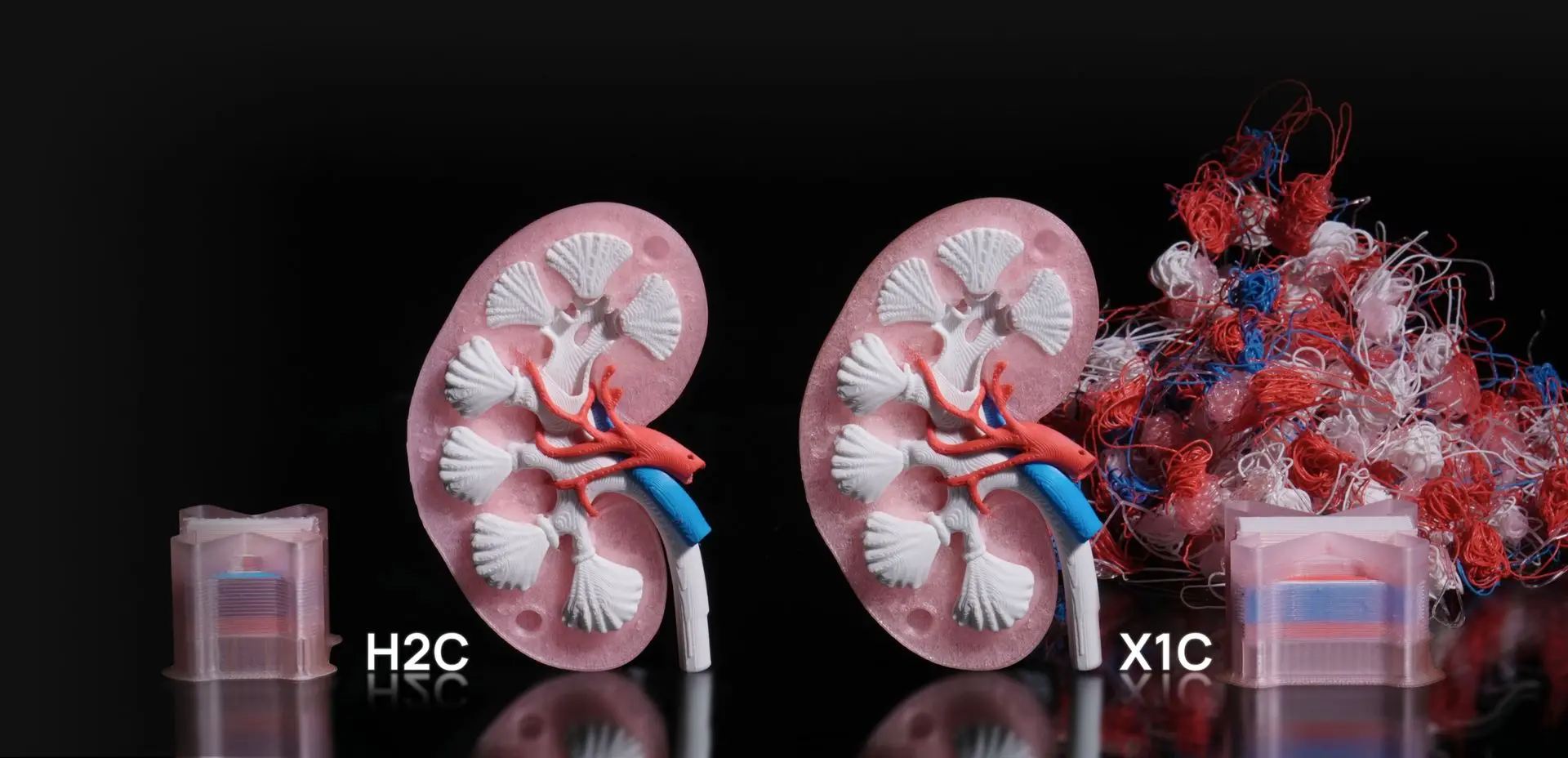

Purge Saving Multi-Color Printing:

Painting intricate models is a thing of the past — the H2C brings your designs to life with six-color printing and a versatile seventh nozzle for support or an additional color. This whole thing is printed in 2 parts. The main raptor is 6-color and the base is another 6-color.

Revolutionize How You Print Your Projects

Bambu Lab Racer

@Mr.Rod

A race car with racing stripes? Yes, you can print it straight out! Forget the hassle of painting or wasting tons of filament.

Purge waste | Print time | |

H2C | 522g | 5d8h54m |

H2D | 2051g | 8d7h2m |

X1C | 2953g | 11d7h57m |

7 Colors. One Print. No Paint.

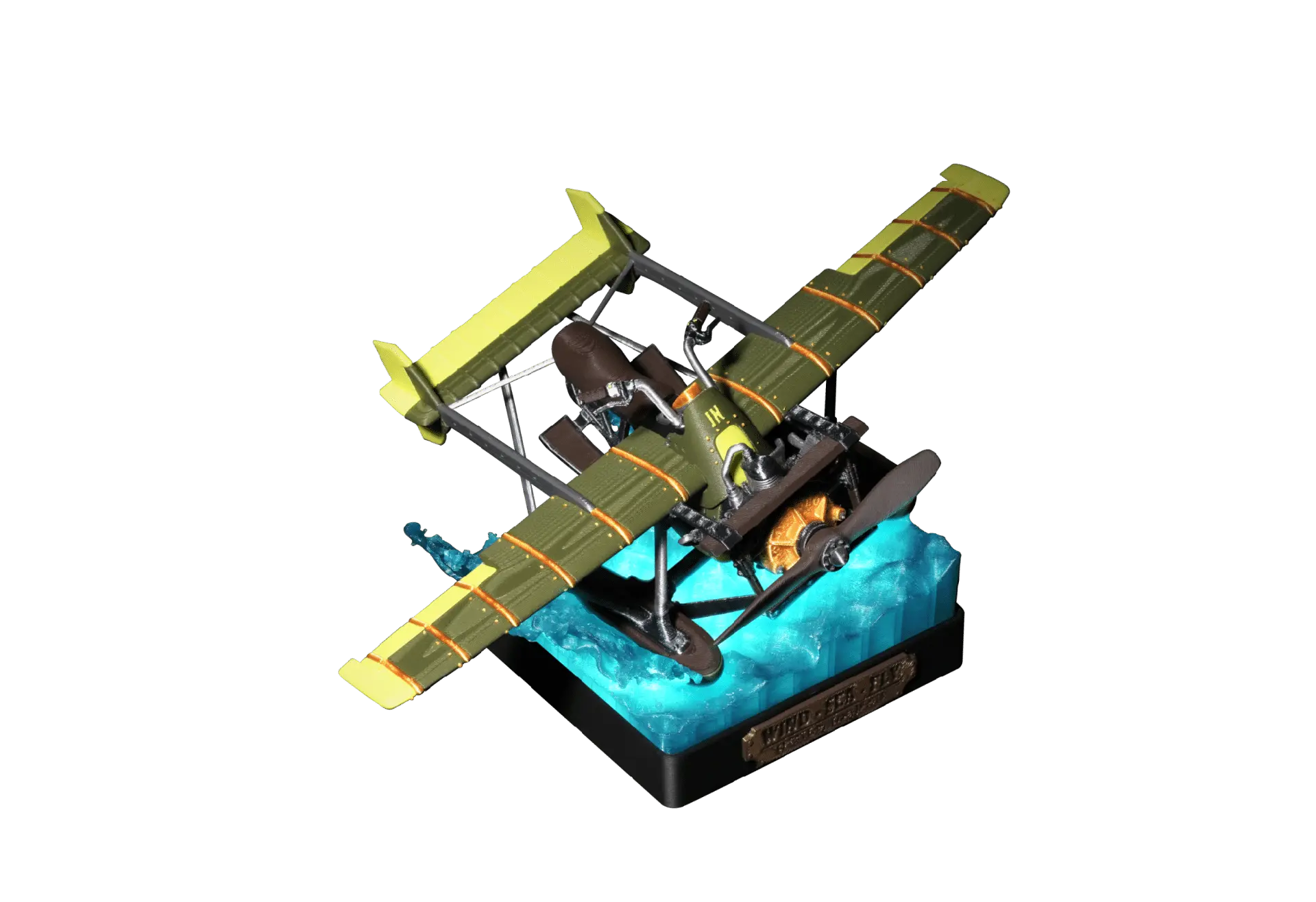

Blériot Rider - XI

@CrazyJN

An anime-style fighter plane in full color — no paint-brushes, no glue, no fuss.Simply load your filaments and print a flawless one-piece model in no time.

Purge waste | Print time | |

H2C | 185g | 1d10h2m |

H2D | 695g | 2d6h59m |

X1C | 768g | 2d20h56m |

Durable Joints, Built Right Into the Parts

Heavy Second Core Mecha

@Kit Crafters

Integrated TPU Joints for Multi-Color Parts.

Print durable TPU ball joints for your robot models — flexible, long-lasting, and built for endless motion.

No More Assembly — Print Multi-Material Parts in One Piece.

Aero Mobius Drone Frame

@极尘悦

With the H2C, you can print up to seven different materials in a single run — no nozzle purging required. Combine multiple material properties in one seamless structure and take integrated design to a whole new level.

Bring Color to Flexible Prints

Multi-Color Sneaker

@CloudBerry

Multi-Color TPU Printing

Bring color and creativity to 3D-printed footwear.With the H2C, you can blend TPU 90A and TPU for AMS to produce multi-color, flexible sneakers that stand out.

Colorway & Torsional Rigidity

Vortek Hotend Change System

Multi-Material Printing with Minimal Purge Waste

In traditional single-nozzle multi-material printing, purging is needed to clear leftover material between filament changes.Vortek changes that with an intelligent hotend-swapping system that replaces the entire hotend — delivering faster, cleaner prints with minimal waste.

Fully Automatic Filament Change

The Vortek system works seamlessly with our highly reliable AMS (Automatic Material System), making the entire filament change process fully automatic — no need to manually load each filament into the toolhead.

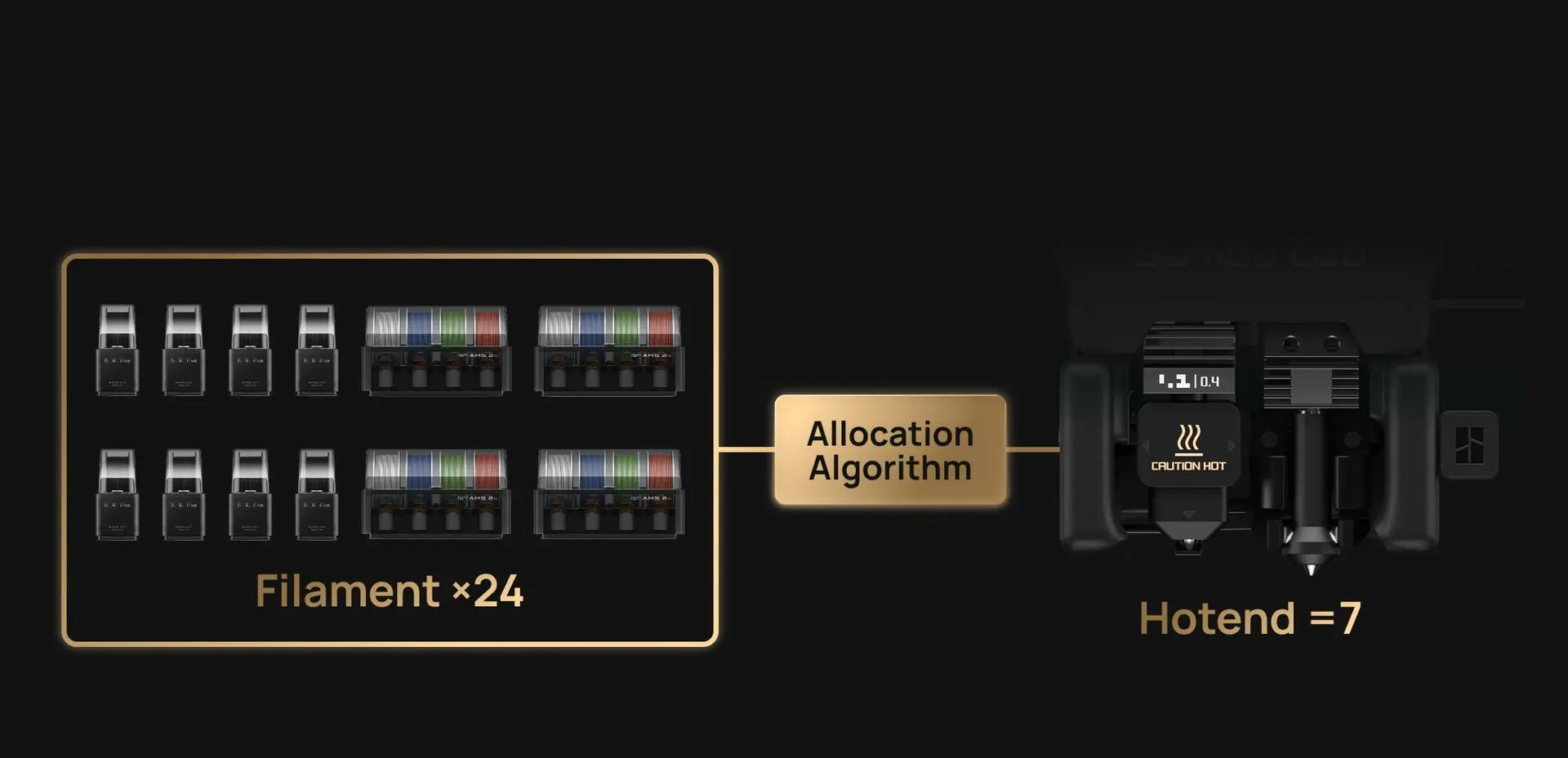

Always Delivering the Most Efficient Combination

The Vortek system can store filament information in the hotend’s memory, ensuring the correct filament is matched to each hotend. If you are printing with more than seven filament types, the system can calculate the optimal combination to minimize purge waste.

Why Vortek?

Small Form Factor, More Filaments

Because only the hotend is swapped, the system can house up to six replaceable hotends without significantly reducing the build volume.That means more materials, more colors, and more possibilities — all in one print.

8-Second Induction Heating

Our industry-leading induction heating technology brings the nozzle to temperature in 8-sec, significantly reducing the preheating time for each material swap compared to traditional methods.

Contactless Design For Reliability

Our high standards for reliability led us to move away from contact-based metal pins, which are prone to oxidation and unstable connections. We developed a contactless solution that ensures a stable, high-frequency connection — the foundation for precise temperature control and intelligent hotend sync.

Colors Are No Longer Limited By How Many Toolheads You Have

Unlike traditional toolchanger printers that limit color count by the number of toolheads, the H2C supports up to 24 materials in a single print through parallel-connected AMS units. Its intelligent algorithm optimizes filament-to-hotend allocation to minimize purge waste while delivering outstanding multi-color and multi-material results.

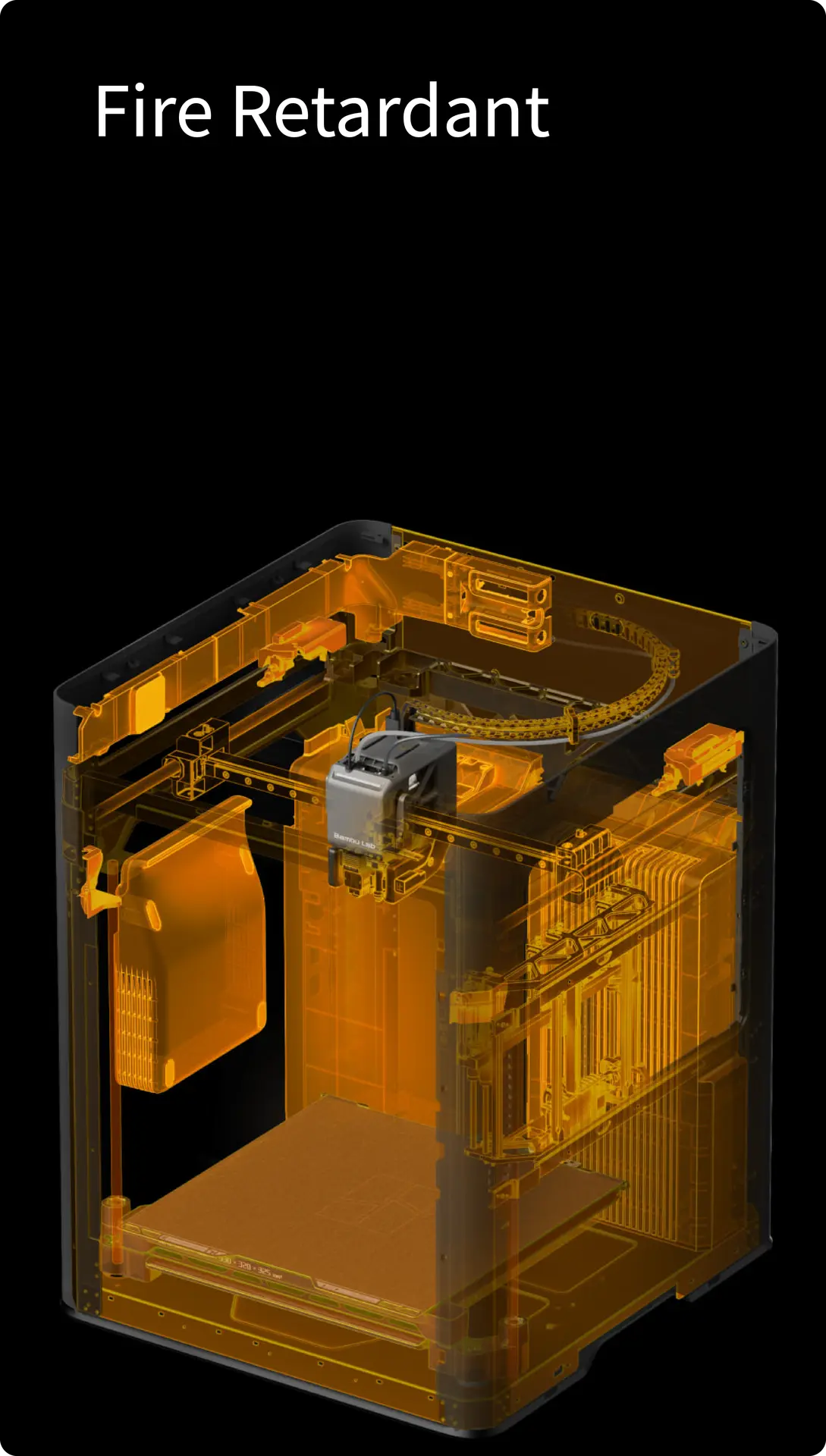

Enclosed for High-Performance Printing

With its seamless enclosure and adaptive airflow system, the H2C maintains a stable chamber temperature for high-performance materials and filters the air to keep your workspace clean and safe.

Fully Automatic Nozzle Offset Calibration

Our inductive nozzle offset calibration is fully automated — no manual steps, no calibration plates, no extra setup. In just a few minutes, the H2C precisely calibrates nozzle offset to within 25 microns.*

Dedicated Hotends for Specific Filaments

The H2C's Vortek system lets you dedicate one of its six interchangeable hotends to specific filaments — a game-changer for valuable engineering materials. This ensures superior consistency and reliability across prints. Each hotend can even automatically store filament information, so the next time you load that material, it's instantly matched to the correct hotend.

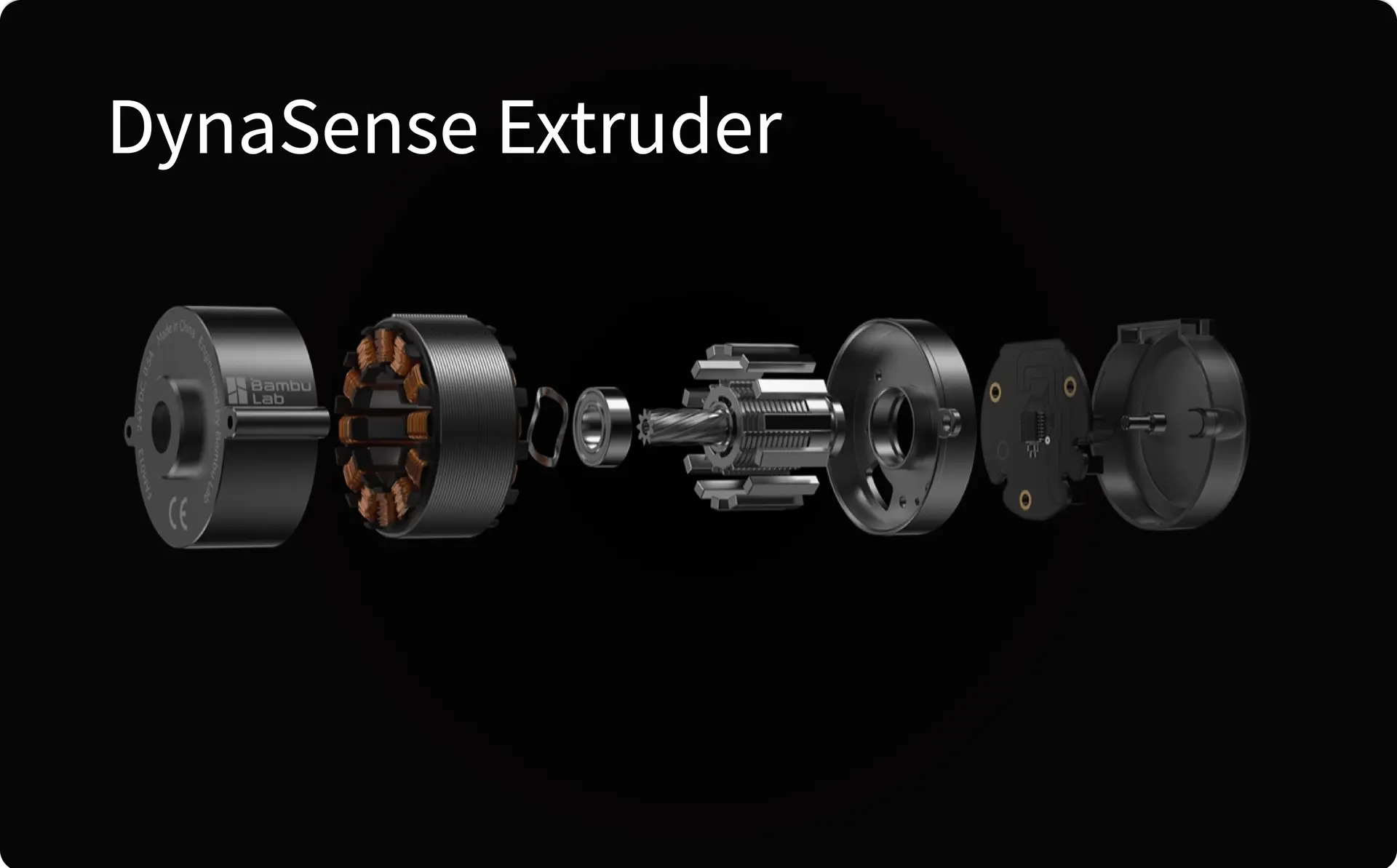

70% More Extrusion Force & Real-Time Error

Detection.

The PMSM servo extruder delivers up to 8.5 kg of maximum extrusion force—70% more than its predecessor—dramatically improves high-flowrate extrusion stability. Our proprietary servo architecture samples resistance and position at 20 kHz, actively detecting filament grinding and clogs in real time.

PMSM Servo Architecture | DynaSense Extruder

50µm Ultra-Fine Motion Accuracy

With its Vision Encoder, the H2C achieves a distance-independent motion accuracy of less than 50 μm—thinner than human hair. The system automatically compensates for any mechanical drift during calibration, ensuring consistent precision and peak performance over time.

The H2C uses the sensing capabilities of both its servo motor on the extruder and the high-resolution eddy current sensors on the nozzle. This allows it to precisely control extrusion and calibrating Pressure Advance (PA) parameters for each filament, resulting in improved surface smoothness and sharp edges.

?unique=bc146ef)

%20(1).webp?unique=138ccd4)

?unique=bc146ef)

%20(1).webp?unique=138ccd4)